Owning a factory, any kind of equipment, or a fleet of vehicles requires maintaining the equipment, machines, or vehicles that are being used. As the cost of maintaining a piece of equipment is usually lower than fixing it, maintaining machinery is one of the most essential things a large manufacturing company can do for itself and its bank account.

Machines and equipment are the backbones of any manufacturing company, with production potentially slowing down or completely stopping every time a machine breaks down. Even one day without the right tools can make it very difficult for businesses to meet their production goals. This is why maintenance is key for business.

Ideally, maintenance is carried out to keep equipment and machinery running efficiently during their usual lifecycle. And since these processes require a lot of effort and time to perform, the need for a system that automates these procedures has become a necessity.

A maintenance management system helps organizations plan, track, measure, and optimize all procedures related to maintenance. It opens the door to new possibilities for the maintenance team. The objective of a maintenance system is to achieve minimum downtime, keep the machines and equipment in good working condition, and minimize cost as much as possible. Machinery should be kept working in a way that permits them to be used at their optimal profit-making capacity without any interruption or hindrance.

Within a maintenance system, manufacturers can get an overview of their plant’s equipment status. They can easily click their way down to every machine and see technical data and figures, installation dates, warranties, spare parts, wiring diagrams, etc. The statistics and data within a maintenance system will provide the best basis for making wise long-term decisions based on facts and not feelings. This way, manufacturers and workers will always be able to know the available spare parts, accurate costs, and how long each process requires.

Schedule work efficiently

Maintenance software allows workers to schedule and assign work orders and inspection rounds quickly and easily. The software allows supervisors to configure work orders and automatically track them in the system. By organizing work orders, everyone will know what tasks are assigned to them. The system can also send time-based reminders to the responsible technician and engineer.

Enhance productivity

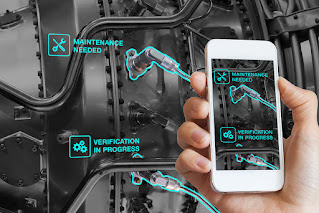

The system enables technicians to access real-time information, check inventory, and initiate work orders even when they are away from the premise. This increases efficiency and productivity because the work is done with minimal interruptions.

Reduce downtime and cost

Maintenance systems give facilities a chance to lower machines idle time by simplifying repairs and detecting problems earlier to prevent machine breakdowns. This helps in keeping equipment in top condition and thus extending their lifespan. Moreover, increasing machinery uptime saves companies the costs associated with downtimes. In addition, these systems track all associated costs to know exactly how the budget is being spent.

Improve Safety

Using an advanced maintenance system, manufacturers can monitor the safety of their machines to eliminate the risk of having poorly-maintained operating assets. This helps factories meet safety requirements and standards that will, in turn, prevent dangerous malfunctions and failures, and makes equipment safer for both operators and the environment.

Eliminate paperwork

Keeping track of maintenance operations manually is cumbersome and requires a lot of paperwork, which makes it even harder to manage. Software system eliminates the need for unnecessary paperwork. The maintenance personnel can view all information related to work orders on their devices so there is no need to print out documents, manuals, or papers.

To wrap up …

A computerized maintenance management system is used to manage everything related to maintenance. It supports businesses in every aspect of their work performed by their maintenance departments. From completing maintenance rounds to tracking metrics and reducing costs and time wastage. They enable companies to increase asset lifetime, enhance productivity, and keep safe work environments. Regardless of what companies trying to achieve, maintenance systems make it easier to accomplish it all.

Looking for a state-of-the-art Maintenance Management System? Click here to learn more about ESKADENIA’s Maintenance Management System.

No comments:

Post a Comment